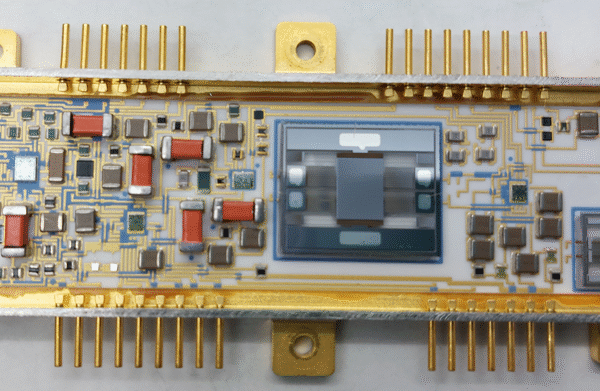

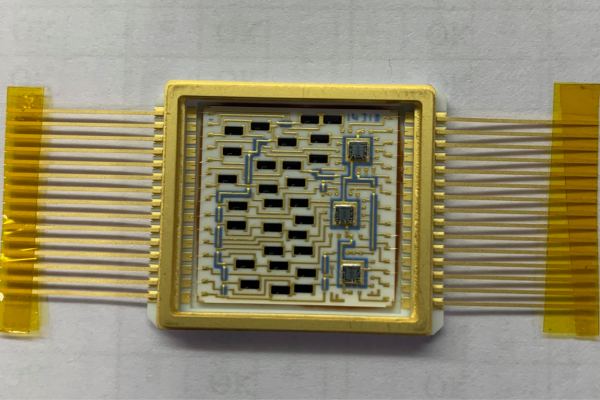

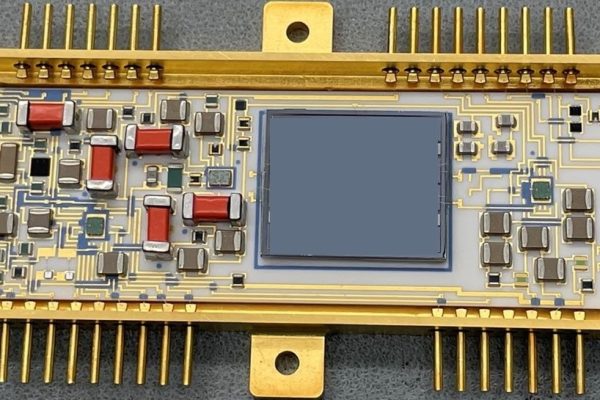

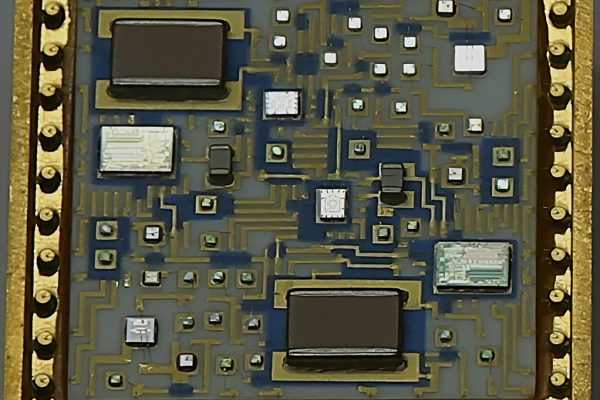

Precision laser trimming is carried out to achieve accurate resistor values, subsequently, components such as ICs, diodes, transistors, chip passives, or dies are mounted. The assembly process involves soldering or wire bonding, followed by hermetic sealing or encapsulation, and marking. Each microcircuit undergoes 100% screening in our in-house reliability screening laboratory, ensuring high performance and compliance with customer specifications.

KHMDL offers microcircuits built to demanding standards, including:

- MIL-PRF-38534 Class-H equivalent for military applications

- MIL-PRF-38534 Class-K for space applications

- Screening matrices as per MIL-STD-883F and specific customer requirements

These capabilities allow KHMDL to deliver compact, rugged, and high-performance hybrid microcircuits tailored to critical application needs.

Specifications

Package and Types

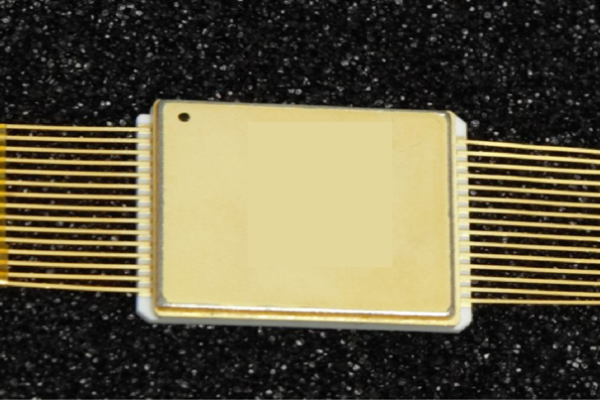

Packages: Hermetically Sealed, Metal / Ceramic

Types: Crossover (Two Layer), Multilayer, Power HMC’s, Digital & Analog HMC’s, Multi Chip Modules

Size

0.7” X 0.7” TO 1.0” X 4”

Specifications

- Conductor Line Width & Spacing : Min 6 Mil

- Wire Bonding, Gold : 0.7 Mil To 1.5 Mil

- No. Of Conductor Layers : 2 To 6 Layers

- Wire Bonding, Aluminium : 1 Mil To 5 Mil

Standard

AS PER MIL STD 883 G

Modules

- Digital

- RF

- Mems

- Discrete devices

- Communication

- Analog devices

- Analog to digital conversion